Numerous Laser Tube Cutting machineries

The Advantages of laser tube technology

- elimination of tools and templates for fixing

- high processing precision, compatible with subsequent welding operations

- possibility of making complex cutting profiles (grooves, joints, holes, slots, inclined cuts, perpendicular cuts, etc.)

- elimination of swarf

- high production flexibility

- possibility of making new solutions and producing them in a few hours

- reduction of the time for making new products, automatic loading of the beam and programmable automatic unloading

- max. unloading length 6000 mm in automatic mode (6500 mm manual)

- minimum waste at end of bar

The forefront of Laser Tube Cutting

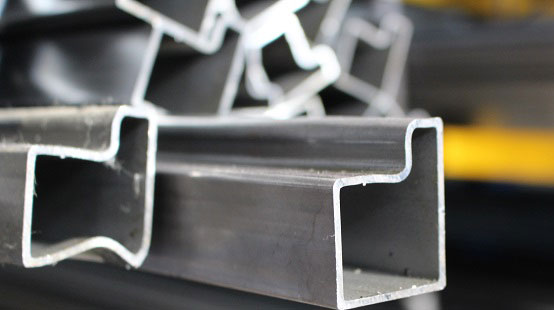

AL.PI is synonymous of Laser Tube Avant-Guarde thanks to special profiles working process.

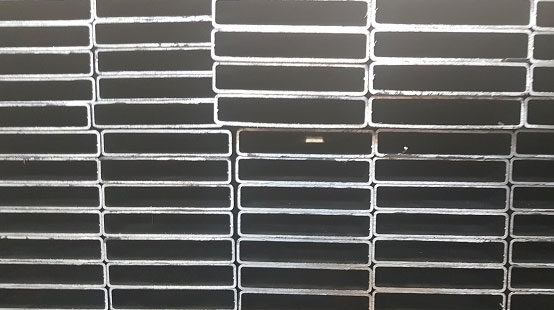

The use of Laser Technology in cutting tubes with different profiles, such as round tubes (with diameter from 10 to 240 mm), elliptical tubes, square tubes (up to diameter 220×220 mm), rectangular tubes (up to diameter 220×200 mm), triangular sections, oval flats, allows considerable advantages to obtained the innovation of the production process, in the high quality level.

Using laser for cutting tubes allows us to work efficiently with materials such as aluminium, stainless steel (8 mm thick), iron (11 mm thick) without needless waste, without transferring the parts to different machines for different operations, without manual loading and unloading and without processing defects and technological non conformities due to the production process, and avoiding the production of moulds.

Tube cleaning device

Intergranted in our Laser Machine, it allows to inhale the dust, residual of the laser working process, to keep clean the pipe’s internal surface.

Bending Metallic pipes without any pipe-bending

We introduce an innovative solution of bend without any pipe-bending machine; a new concept that use the laser cut: we make some cuts on the pipes so can manually bend the pipes, to obtein an economy in the metallic frame production.

Our machineries

- LASER TUBE LT8.20

- LASER TUBE LT7

- LASER TUBE LT FIBER

- LASER TUBE LT8

- LASER TUBE LT 722

- LASER TUBE LT 712 D

- LASER TUBE LT 652 BIG

- METAL SHEET LASER FIBRA PRIMAPOWER 3000X1500

- METAL SHEET VERTICAL STORAGE

- VERTICAL STORAGE TOOLS

- COSTA MD6 POLISHER – CVC + S 1350

- PRESS BRAKE PRIMA POWER

- CARPENTRY

Composed of bench and traditional drills, thread cutter, presses, press brake, band saws, cropping saws, grinding machines, bevelling machine, groove cutter, stapler, grinders - KWBENDING MACHINE WITH 2 ROLLERS

- LONGITUDINAL WELDERS

- CUTTING AND ROUNDING CENTRE FOR ROUND PIPES

- PIPE BENDING

- SHEARING

- C.N.C. TURNING CENTRE

- 2 C.N.C WORK STATIONS

- AUTOMATIC CIRCULAR TIG WELDERS

- N.8 MANUAL TIG WELDING STATIONS

Processed materials

Stainless Steel, Brass, Copper, Aluminum, Iron, Corten, Domex